In the world of construction and industrial manufacturing, the stability and safety of any structure—from skyscrapers to heavy machinery—rely fundamentally on the quality of its most fundamental components. Among these, anchor foundation bolts are indispensable, providing the critical connection between structural elements and their concrete foundations. For engineers, project managers, and procurement specialists, selecting the right anchoring solutions is a decision that impacts not only compliance but long-term safety and durability.

At JM Hardware® (Shanghai Jian & Mei Industry & Trade Co., Ltd.), we specialize in the design and manufacturing of high-performance anchor foundation bolts that meet the rigorous demands of global construction and industrial applications. Our products are engineered to deliver exceptional holding power, corrosion resistance, and adaptability to diverse environments and load conditions.

What Are Anchor Foundation Bolts?

Anchor foundation bolts, also referred to as foundation anchors, structural anchors, or holding-down bolts, are fasteners used to securely attach structural elements to concrete or masonry. They are designed to transfer loads—both static and dynamic—from the structure to the foundation, ensuring stability under various conditions such as wind uplift, seismic activity, or the operation of heavy machinery.

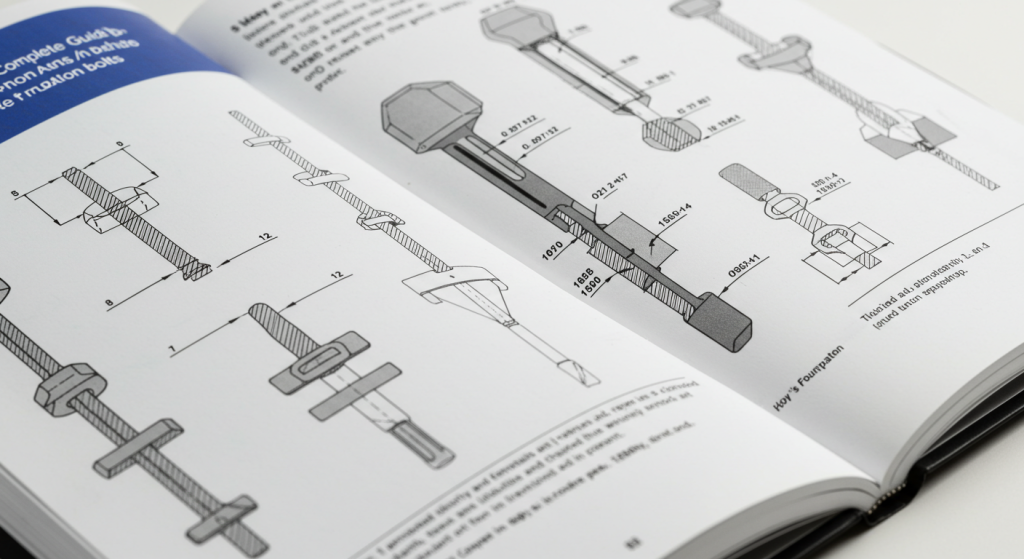

Common types include:

Wedge Anchors: Ideal for high-load applications in solid concrete.

Sleeve Anchors: Versatile and suitable for a range of base materials.

Drop-In Anchors: Used for flush-mounted applications.

Chemical Anchors: Provide superior strength in cracked or weak concrete.

Each type serves specific purposes, and selecting the appropriate bolt depends on factors like load capacity, environmental conditions, and substrate material.

Industrial Applications of Anchor Foundation Bolts

Anchor bolts are critical across a wide range of sectors:

Construction: Securing steel columns, pre-fabricated structures, and heavy machinery to concrete foundations.

Infrastructure: Ensuring the cohesion and stability of bridges, tunnels, and highways.

Energy Sector: Anchoring equipment in power plants, wind turbines, and oil rigs.

Manufacturing: Fastening machinery to factory floors to minimize vibration and displacement.

In all these applications, the reliability of the anchor bolt directly influences safety, operational

Why Source Anchor Bolts from JM Hardware®?

As a leading anchor bolt manufacturer in China, JM Hardware® has built a reputation for excellence in the global hardware supply industry. Here’s what distinguishes our products and services:

Superior Materials: Our bolts are manufactured from high-strength carbon steel, stainless steel, or alloy materials, treated with anti-corrosion coatings such as hot-dip galvanizing or zinc plating to ensure extended service life even in harsh environments.

Precision Engineering: Every bolt is designed to meet international standards (e.g., ISO, ASTM, ASME B18.2.6) and is rigorously tested for tensile strength, shear resistance, and fatigue performance.

Customization Capabilities: We offer tailored solutions for unique project requirements, including non-standard sizes, materials, and threading specifications, ensuring perfect compatibility with your design specifications.

Global Supply Chain Efficiency: Based in Shanghai, we serve clients worldwide with reliable logistics and timely delivery, supported by our extensive experience in international trade.

Technical Expertise and Support: Our team provides end-to-end support, from product selection and installation guidance to after-sales service, ensuring optimal performance and customer satisfaction.

Selecting the Right Anchor Bolt: A Practical Guide

Choosing the correct anchor foundation bolt involves careful consideration of several factors:

Load Requirements: Determine the tensile, shear, and combined loads the bolt must withstand.

Environmental Conditions: Assess exposure to moisture, chemicals, or temperature extremes.

Substrate Properties: Evaluate the quality and type of concrete or masonry.

Installation Method: Mechanical anchors offer quick installation, while chemical anchors provide higher strength in challenging substrates.

For specialized applications, consulting with an experienced anchor bolt supplier like JM Hardware® can prevent costly errors and ensure optimal performance.

JM Hardware®: Your Trusted Partner for High-Performance Fastening Solutions

As a prominent anchor bolt manufacturer and supplier in China, JM Hardware® is committed to delivering products that exceed expectations. Our dedication to quality, innovation, and customer satisfaction has made us a preferred partner for contractors, engineers, and distributors globally.

Explore our comprehensive range of anchor foundation bolts and other fastening solutions on our website:

https://www.jm-industry.com/

Whether you’re working on a skyscraper, an industrial plant, or a critical infrastructure project, trust JM Hardware® to provide the foundational strength your structure demands.